Înțelegerea tehnologiei rolelor vibrante și a mecanicii de bază

Cum funcționează rolele vibrante: Știința din spatele vibrației și al compactării

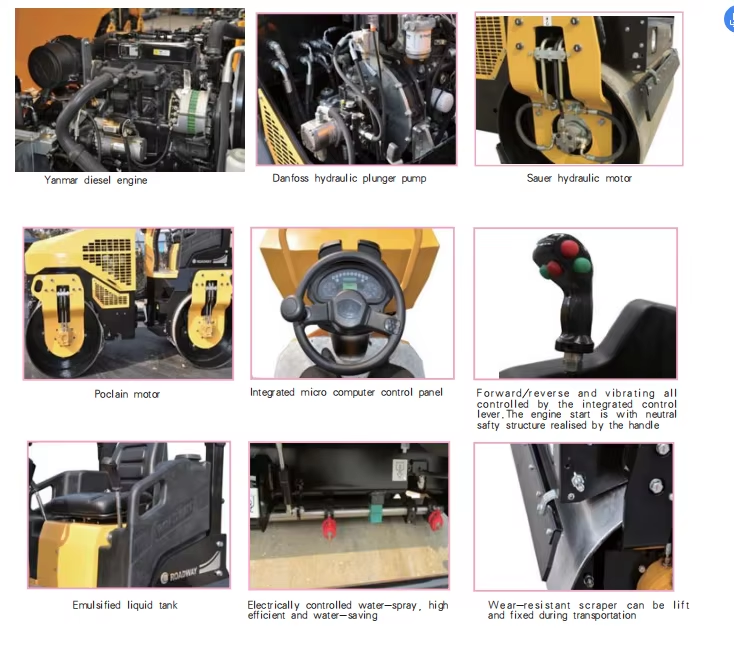

Rolele vibrante funcționează prin apăsarea materialului în timp ce îl și zgâlțâie. Mașina are o componentă numită masă excentrică care se rotește foarte repede în interiorul rolei. Această rotație creează o forță de tracțiune care face ca rola să sară în sus și în jos pe măsură ce se deplasează. Atunci când acest lucru se întâmplă, solul de dedesubt devine mai ușor de comprimat, deoarece particulele mici de pământ pot aluneca și se pot așeza mai strâns. Majoritatea mașinilor moderne sunt echipate cu supape speciale care controlează cantitatea de ulei trimisă către diferite părți ale sistemului hidraulic. Acest lucru ajută la menținerea unui vibrații constante la aproximativ 25-40 de ori pe secundă, ceea ce s-a dovedit a fi ideal pentru obținerea unor rezultate optime atunci când se lucrează cu soluri nisipoase sau pietroase. O cercetare publicată anul trecut în Nature susține acest lucru, arătând că aceste game de frecvență produc efecte optime de compactare.

Indicatori cheie de performanță: Amplitudine, Frecvență și Forță centrifugă

Trei indicatori principali determină eficacitatea rolelor vibrante:

- Amplitudine (0,4–2 mm): Deplasare verticală care influențează adâncimea de compactare

- Frecvență (1.500–3.000 vibrații/minut): Viteză de oscilație care afectează densitatea suprafeței

- Forța centrifugă (20–350 kN): Energia de impact generată de masele excentrice rotative

Amplitudinile mai mari (~2 mm) sunt cele mai potrivite pentru straturile profunde de subsoil, în timp ce frecvențele peste 2.500 VPM oferă o finisare superioară pe suprafețele din asfalt. Unitățile moderne folosesc senzori integrati pentru a ajusta automat aceste parametri în funcție de rezistența materialului.

Principalele tipuri de role vibrante și diferențele lor mecanice

Rolele vibrante sunt clasificate în funcție de designul tamburului și domeniul de aplicare:

| TIP | Mecanism | Cel Mai Bine Pentru |

|---|---|---|

| Cu un singur tambur | Tambur vibrant + anvelope pneumatice | Straturi de bază, soluri stâncoase |

| Tandem | Două tamburi vibrante (1,5–18 tone) | Asfalt, materiale granulare |

| Platou de tip ciocan (Sheepsfoot) | Tambur segmentat cu picioare proeminente | Argilă coezivă, depozit de deșeuri |

| Combinație | Tambur vibrant + roată statică | Proiecte multicapa |

Modelele cu un singur tambur se remarcă în lucrări mari de terasamente, atingând până la 100% eficiență în umpleri stratificate, în timp ce rolele tandem obțin o densitate de peste 95% în asfalt, folosind două tamburi cu o forță centrifugă de 1.800 lb/ft.

Potrivirea tipurilor de role vibrante cu aplicațiile și condițiile solului

Role netede pentru finisarea asfaltului și compactarea suprafețelor

Rolele vibrante cu tambur neted oferă o uniformitate excepțională a suprafeței, fiind ideale pentru pavajul asfaltic și compactarea bazei granulare. Funcționând la frecvențe înalte (2.500–4.000 VPM), ele elimină golurile de aer fără a deteriora structura agregatului—un factor esențial, deoarece NAPA (2023) raportează că o scădere cu 1% a densității carosabilului poate reduce durata de viață cu 15%.

Role compactor cu role ciocane (Sheepsfoot) pentru compactare adâncă în soluri coezive

Rolele zimate de la rolele compactor cu role ciocane dezvoltă o forță considerabilă în ceea ce privește compactarea solului. Aceste suprafețe texturate concentrează mai bine forța, permițând pătrunderea mai profundă în soluri dificile, cum ar fi argila densă și nisipul lipicios. În comparație cu rolele obișnuite cu tambur neted, modelele cu role ciocane realizează de obicei cu aproximativ 30 la sută mai multă adâncime de compactare, ceea ce explică de ce inginerii le preferă pentru construcția barajelor și amenajarea sistemelor de etanșare la gropile de gunoi. Testele efectuate în teren indică faptul că majoritatea modelelor de role compactor cu role ciocane ating aproximativ 95 % din densitatea Proctor maximă după doar trei treceri prin teren argilos. Un asemenea randament face toată diferența în proiectele unde compactarea corectă este absolut esențială.

Role compactor pneumatice și role compactor tandem pentru etanșare specializată și proiecte cu straturi multiple

Rolele pneumatice utilizează o presiune reglabilă în anvelope (40–100 psi) pentru a se adapta la umpluturi mixte sau variabile, în timp ce rolele tandem aplică forțe statice și vibratoare pe mai multe straturi. Împreună, acestea reduc ruperea suprafeței în solurile amestecate cu până la 40% comparativ cu alternativele cu un singur tambur.

Role manuale și compacte pentru șantiere mici și urbane

Rolele compacte manuale (1–3 tone) oferă o manevrabilitate excelentă în spații strânse, lățimile de 24"–36" permițând accesul la 85% dintre zonele confinate inaccesibile mașinilor mai mari. Nivelul redus de zgomot – care crește nivelul ambiental doar cu ~5 dB – le face conforme cu reglementările urbane privind zgomotul.

Compatibilitate cu tipul de sol: Alegerea rolei potrivite pentru argilă, nisip, pietriș și umpluturi mixte

- Argilă/Soluri lipicioase : Rolele cu proeminente previn întinderea prin puncte concentrate și alternante de presiune

- Nisip/Pietriș : Modelele cu tambur neted promovează rearanjarea particulelor prin vibrație

- Umpluturi multic strat : Rolele pneumatice ajustează dinamic presiunea de contact cu solul

- Materiale reciclate : Unitățile tandem cu setări duble de amplitudine (50/70 kN) gestionează eficient densitățile inegale

Potrivirea dimensiunii și puterii rolei cu amploarea proiectului: de la alei până la autostrăzi

Selectarea echipamentului trebuie să corespundă scalei proiectului. Pentru alei și parcele mici, rolele compacte sub 5 tone îmbunătățesc eficiența combustibilului cu până la 22% și sporesc manevrabilitatea pe șantier. În schimb, proiectele de autostrăzi necesită role peste 10 tone, cu frecvențe de 35–40 Hz, pentru a asigura o densitate de compactare de 95% pe secțiuni largi de asfalt.

Cele mai bune aplicații în construcția drumurilor, gropi de gunoi și lucrări de fundație

Rolele vibrante îndeplinesc roluri diverse și esențiale:

- Lucrări rutiere : Modelele cu tambur neted etanșează suprafețele uniform la 2–4 km/h

- Depozite de deșeuri : Variantele cu picioare conice pătrund 8–12 inch în straturile de deșeuri pentru stabilizare

- Fundații : Rolele tandem realizează o densitate Proctor de 90–98% în pregătirea stratului de fundație

Alegerea necorespunzătoare a rolei crește numărul de treceri necesare cu 40% în solurile bogate în argilă, conform unui studiu din 2023 privind eficiența compactării.

Tendințe în infrastructura urbană: Cerere crescută pentru role vibrante compacte și manevrabile

Constrângerile urbane determină o creștere anuală de 31% în cazul rolelor vibrante compacte manuale și cu operator (sub 3 tone). Aceste utilaje funcționează eficient în coridoare înguste de 1,8 metri și respectă standardele de emisii Tier 4. Sistemele electrice de vibrare sunt adoptate tot mai frecvent în zonele subterane și pietonale, oferind o forță centrifugală de 18–22 kN fără emisii de gaze de eșapament.

Eficiența compactării: Reducerea numărului de treceri și îmbunătățirea uniformității densității

Ultimul model de role vibrante funcționează mai bine deoarece forța dinamică este adaptată vitezei de vibrație. Când muncitorii ajustează amplitudinea în funcție de grosimea stratului de sol, adesea trebuie să treacă de mai puține ori peste același loc—cam cu 30-40 la sută mai puțin. Acest lucru este foarte important atunci când se urmărește respectarea standardelor ASTM pentru compactarea drumurilor, unde se dorește o densitate de cel puțin 95% în materialele de bază. Constructorii care folosesc aceste mașini raportează că rezultatele sunt cu aproximativ 2-3 procente mai constante în comparație cu rolele statice clasice, mai ales când lucrează pe teren nisipos sau pietros.

Optimizarea setărilor de amplitudine și frecvență pentru diferite straturi de material

Compactarea eficientă necesită o reglare precisă:

- Asfalt : amplitudine 0,7–1,5 mm, frecvență 25–35 Hz

- Strat de fundație : amplitudine 1,8–2,2 mm pentru consolidare profundă

- Pământuri granulare : 25–35 Hz pentru o așezare optimă a particulelor

- Argile coezive : 20–25 Hz pentru a evita rebotele de suprafață

Sistemele adaptive de vibrații ajustează acum automat forțele centrifuge (20–35 kN) în funcție de feedback-ul în timp real al materialului, sporind eficiența cu 18% în operațiunile cu mai multe ridicări.

Dezbatere: Forța vibratoare versus greutatea statică în atingerea densității optime a solului

Rolele vibratoare obțin în mod tipic densități cu 3–5% mai mari în argilă decât modelele statice și necesită cu 15% mai puțină energie pe yard cub în amestecuri de nisip-piatră. Totuși, rolele statice rămân preferabile pentru straturile subțiri de asfalt, unde vibrația înaltă frecvență poate provoca fisurarea agregatelor, depășind unitățile vibratoare cu 20% în viteză în astfel de condiții.

Costul total de proprietate: Buget, întreținere și pregătire pentru viitor

Investiția inițială versus rentabilitatea pe termen lung pentru diferite modele de role vibratoare

Prețul de etichetă ar putea atrage atenția întâi, dar ceea ce determină cu adevărat dacă ceva este rentabil pe termen lung sunt costurile recurente care se acumulează lună de lună. Datele recente din studii privind echipamentele de construcții arată că elemente precum întreținerea regulată, consumul de combustibil și tot timpul pierdut atunci când mașinile se defectează reprezintă între 60 și 75 la sută din cheltuielile efective ale companiilor pentru deținerea echipamentelor pe o perioadă de zece ani. Compactoarele tandem grele presupun într-adevăr o investiție inițială mai mare, de obicei cu 20-40 la sută mai mare decât modelele standard. Totuși, antreprenorii care lucrează la proiecte mari tind să considere aceste mașini profitabile, deoarece necesită mai puține treceri pentru a finaliza corect lucrarea și rămân în funcțiune mai mult timp între reparații, ceea ce se traduce printr-un randament mai bun atunci când se analizează rezultatul financiar al operațiunilor majore.

Întreținere, durabilitate și disponibilitatea pieselor în funcție de tipul de compactor

Rolele cu talpă canelată suportă tensiuni mai mari de vibrație, necesitând înlocuirea rulmenților cu 30% mai frecvent decât modelele cu tambur neted. Rolele cu pneuri au uzură mecanică mai redusă, dar costuri mai mari pentru înlocuirea anvelopelor. Alegerea unor modele cu componente standardizate îmbunătățește disponibilitatea, mai ales atunci când sunt susținute de producători care oferă livrare piese în 24 de ore.

Eficiență combustibil, intervale de întreținere și economii de costuri operaționale

Noile role vibrante diesel sunt cu 8–12% mai eficiente din punct de vedere al consumului de combustibil decât modelele vechi, economisind 1.200–2.500 USD anual pe proiectele majore de drumuri. Rolele compacte electrice elimină complet utilizarea combustibilului, dar necesită investiții în infrastructura de încărcare. Sistemele de telemetrie ajută la optimizarea programelor de întreținere, reducând reparațiile neprogramate cu 55% (Ponemon 2023).

Tendințe emergente: role vibrante electrice, hibride și automate

Se preconizează că piața rolelor vibratoare electrice va crește cu 18% anual până în 2030 (Gartner 2024), stimulată de obligațiile municipale privind emisiile zero. Modelele hibride comută între modurile electric și diesel pentru a echilibra performanța ecologică cu puterea. Rolele complet automate, echipate cu sisteme de cartografiere a compactării bazate pe inteligență artificială, reduc costurile cu forța de muncă cu 25% în proiectele de infrastructură inteligentă.

Echilibrarea inovației și pregătirii forței de muncă în adoptarea rolelor high-tech

Deși recunosc creșterea eficienței, 58% dintre antreprenori semnalează lacune de competențe ale operatorilor în gestionarea sistemelor avansate de telemetrie (Studiu ACME 2024). Pentru a acoperi această lacună, implementați o instruire treptată – începând cu controlul vibrațiilor de bază, înainte de a trece la monitorizarea densității în timp real. Parteneriatele cu producători care integrează module de instruire în interfețele mașinilor accelerează dobândirea competențelor și adoptarea.

Întrebări frecvente

Care sunt principalele beneficii ale utilizării rolelor vibratoare față de rolele statice?

Rolele vibrante realizează densități mai mari ale solului și necesită mai puține treceri, în special în amestecurile de argilă și nisip-piatră. Ele funcționează și mai eficient datorită forței dinamice și capacității de potrivire a frecvenței de vibrație.

Cum influențează amplitudinea și frecvența performanța rolelor vibrante?

Amplitudinea afectează adâncimea de compactare, în timp ce frecvența influențează densitatea suprafeței. Amplitudinile mai mari sunt pentru straturi mai profunde, iar frecvențele mai mari oferă finisări superioare, în special pe asfalt.

Ce tipuri de role vibrante sunt potrivite pentru suprafețe asfaltice și granulare?

Rolele tandem și cu tambur neted sunt ideale pentru materiale asfaltice și granulare, deoarece oferă o uniformitate excepțională și o reorganizare optimă a particulelor prin vibrație.

Sunt rolele electrice o opțiune viabilă pentru proiectele de construcții?

Da, rolele electrice sunt din ce în ce mai populare datorită emisiilor zero, fiind potrivite pentru proiecte urbane și prietenoase cu mediul. Cu toate acestea, necesită o investiție în infrastructura de încărcare.

Cuprins

- Înțelegerea tehnologiei rolelor vibrante și a mecanicii de bază

-

Potrivirea tipurilor de role vibrante cu aplicațiile și condițiile solului

- Role netede pentru finisarea asfaltului și compactarea suprafețelor

- Role compactor cu role ciocane (Sheepsfoot) pentru compactare adâncă în soluri coezive

- Role compactor pneumatice și role compactor tandem pentru etanșare specializată și proiecte cu straturi multiple

- Role manuale și compacte pentru șantiere mici și urbane

- Compatibilitate cu tipul de sol: Alegerea rolei potrivite pentru argilă, nisip, pietriș și umpluturi mixte

- Potrivirea dimensiunii și puterii rolei cu amploarea proiectului: de la alei până la autostrăzi

- Cele mai bune aplicații în construcția drumurilor, gropi de gunoi și lucrări de fundație

- Tendințe în infrastructura urbană: Cerere crescută pentru role vibrante compacte și manevrabile

- Eficiența compactării: Reducerea numărului de treceri și îmbunătățirea uniformității densității

- Optimizarea setărilor de amplitudine și frecvență pentru diferite straturi de material

- Dezbatere: Forța vibratoare versus greutatea statică în atingerea densității optime a solului

-

Costul total de proprietate: Buget, întreținere și pregătire pentru viitor

- Investiția inițială versus rentabilitatea pe termen lung pentru diferite modele de role vibratoare

- Întreținere, durabilitate și disponibilitatea pieselor în funcție de tipul de compactor

- Eficiență combustibil, intervale de întreținere și economii de costuri operaționale

- Tendințe emergente: role vibrante electrice, hibride și automate

- Echilibrarea inovației și pregătirii forței de muncă în adoptarea rolelor high-tech

-

Întrebări frecvente

- Care sunt principalele beneficii ale utilizării rolelor vibratoare față de rolele statice?

- Cum influențează amplitudinea și frecvența performanța rolelor vibrante?

- Ce tipuri de role vibrante sunt potrivite pentru suprafețe asfaltice și granulare?

- Sunt rolele electrice o opțiune viabilă pentru proiectele de construcții?